Screening Wall Replacement

Once the retaining wall and piers have been corrected and finished, the demolition and rebuilding of the above grade screening wall begins. Our custom cut galvanized angle irons and custom shipped brick match paired with Type S matching mortar allows for the columns to be repurposed through most of the wall.

Screening Walls

All of the all of the screening wall panels and pocket columns in this neighborhood have been rebuilt due to rusted track wire and pier movement of the columns. You can see the accents on the panels and columns showing a variety of color chosen by the HOA from samples recommended by Brick & Stone Master.

Brick Wall Removal

We make quick work of removing the existing wall to clear the space for the new angle irons to support the new brick panels.

Brick Delivery

We coordinate efforts with each HOA and property to ensure the best available brick match is selected to meet their custom project.

Dumping Clean Fill Brick

Our brick are recycled at the landfill to be made one with earth once again after their lifespan is complete.

Brick Wall Demolition

After demoing the panels to the ground, when accessible we will use our skid steer bucket to expedite the loading and hauling off of the old material.

Brick Matching Experts

We take price in being the best company with the most information to make the best decision for the community when it comes to brick matching.

Hot Dipped Galvanized Angle Iron

Homeowner New Masonry Columns

These columns were drawn up by our design experts who submitted plans and drawings to then work with the city through the permitting process for the homeowner.

Newly Built Section of Brick Wall

We take pride in our work during the project and ensure by the end, not a brick chip is left behind during cleanup.

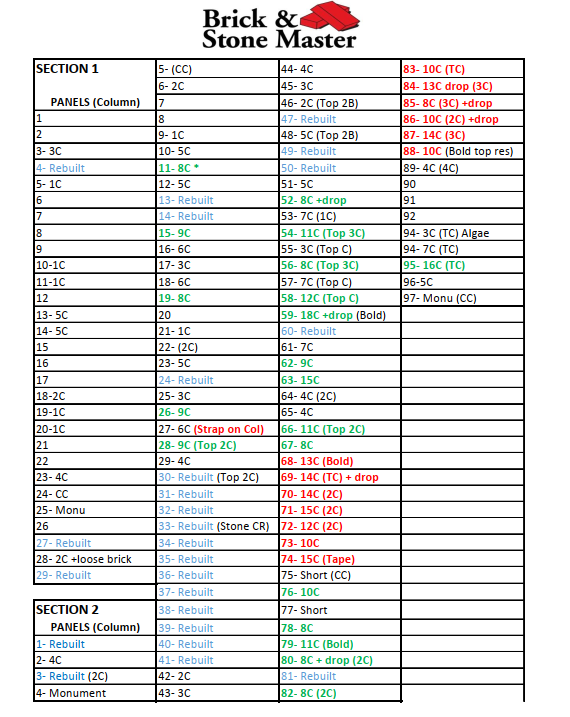

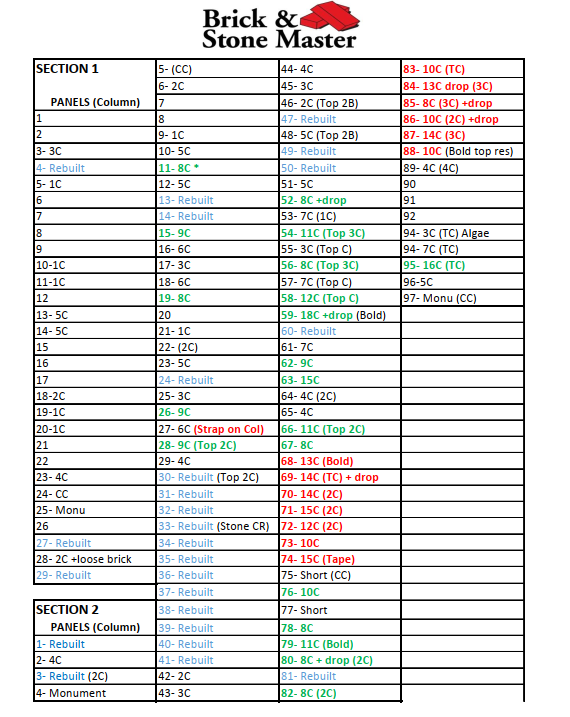

Screening Wall Site Plan

This is one of our 2019 site plan neighborhoods. As you can see, we track the digression of the individual walls on an annual basis, only rebuilding the top priority each year. We can set expectations and future analysis cost as well throughout this process.

Rusted Track Wire Inside Panels

We separate all of the rusted wire carefully when demoing the existing panels so it can be recycled properly and safely.

Rusting Wire without Angle Iron Support

Here you can see the amount of integrity loss due to the rusting ladder wire on the inside of the panel. This causes the mortar joints to deteriorate and without an angle iron support they will drop in the center.

Next Phase of Panel Rebuilds

We will work with HOA budgets when needed to optimize and prioritize the worst sections throughout the perimeter. You can see the old brick and the rusting ladder wire on the left panel, and the new brick with accents on the right. The skirt along the bottom was also eliminated to reduce future maintenance.

Brick Wall Repair

These perimeter walls have lost 100% of the integrity and now they must be built out of emergency necessity versus pro activeness. Cities will fine neighborhoods throughout DFW that allow their walls to deteriorate to this point and they become a major safety hazard to homeowners.

Brick by Brick Rebuilding New Panels

This is a new brick from mock panels built by Brick & Stone Master to match a 20 year old failing screening wall in Southlake, Texas.

Demoing Existing Panel

It isn’t always easy to knock down and remove these walls when they are laced back into the adjacent columns or if they are 20’+ long like this panel is.

Precision Brick Laying

We measure out each bond to commercial standards and tool the mortar at the appropriate time.

Column For Privacy Surround

This is a Lueder Stone Column with a Brick Accent to Match the House